HOW TO IMPROVE ELECTRONIC COMPONENTS' DURABILITY?

Overpressure, dust and moisture can be dangerous for every sealed enclosure. That's why housing ventilation is a decisive issue, especially in the automotive and electronics sectors.

We manufacture several millions of ePTFE membranes each year. That makes us a reliable partner and an expert in the development of performing venting membranes.

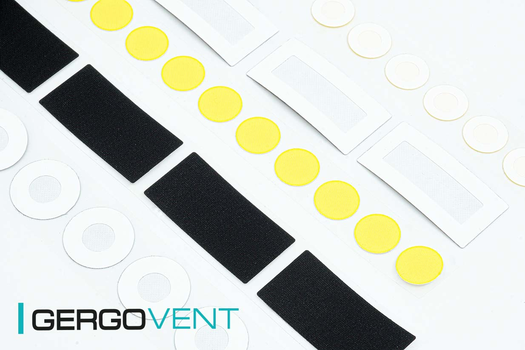

Our adhesive venting membranes from the Gergovent range protect your sealed enclosures from water and dust while evacuating heat (generated by electronic components), overpressure and moisture.

Depending to your needs, we can offer two venting membranes references (VM-13 and VM-15) with different air flow and MVTR. Both of our references resist to extreme temperatures between -40°C to +150°C and are available in 4 standard sizes (rectangle and circle). Our adhesive venting membranes are also PFOA-free and dicyclohexyl phthalate- free.

Do you need tailor-made adhesive venting membranes?

As an expert in die-cutting of parts, we can cut the adhesive venting membranes according to your requirements. Ask for our brochure to know more!

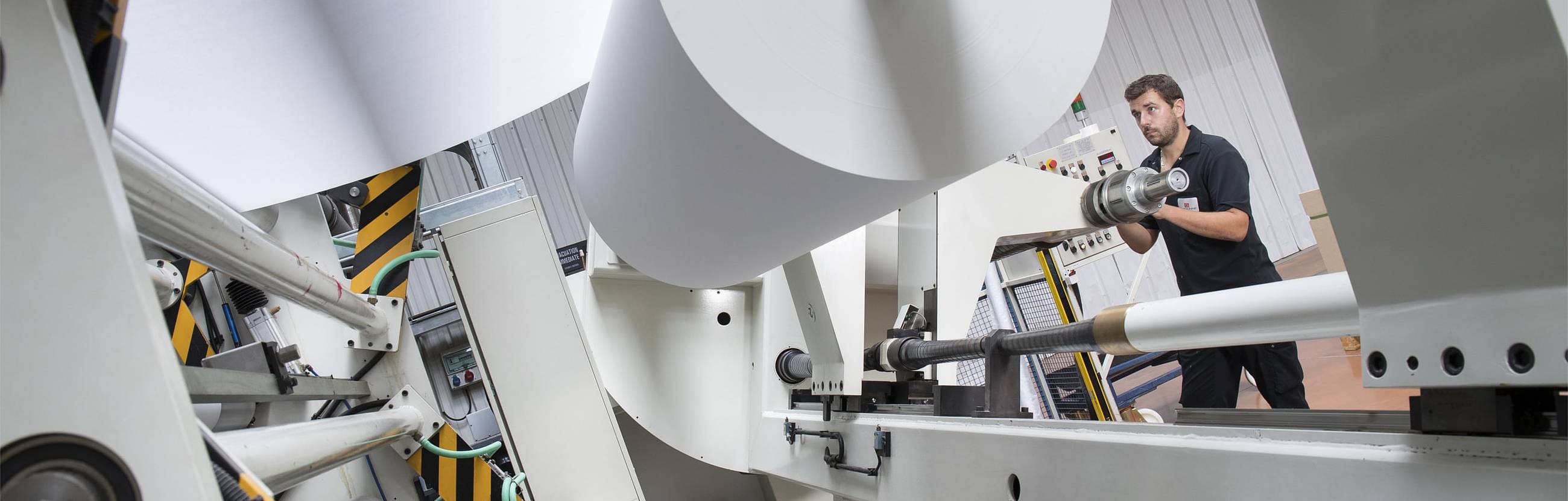

Thanks to our synchronised rotary die-cutting machines including vision control, all of our adhesive venting membranes are compliant with the original drawing.

By using Gergovent venting membranes you have the guarantee to ensure your product a good performance and a longer lifespan.

Contact us for more information!