Nachrichten

VENTASEAL RANGE :Unser Sortiment an luftdichten Klebebändern für die Bauindustrie

Sie kannten bereits unsere luftdichten Klebebänder für die Bauindustrie… aber jetzt können Sie sie unter dem Namen VENTASEAL neu entdecken! VENTASEAL vereint nun alle unsere führenden und standardmäßigen Klebebandlösungen für...

SUCHEN SIE NACH ZUVERLÄSSIGEN KLEBSTOFFLÖSUNGEN FÜR DIE VERBINDUNG?

Mit seiner GERGOSIL-Produktreihe bietet Gergonne als Hersteller von Silikonklebebändern doppelseitige Silikonklebebänder der Typen 900D und 904D an, die für die Verbindung von Silikonpapier oder -folie zu einer durchgehenden Länge sowie...

FLEXOGRAFISCHE DRUCK-LÖSUNGEN – UNSER EINSEITIGES SCHAUMKLEBEBAND FÜR DIE NACHDRUCK-MONTAGE

Gergonne Industrie ist auf den Markt für Flexodruck nach dem Druck spezialisiert und bietet eine breite Palette an einseitigen Klebebändern, die eine optimale Druckqualität garantieren. Unsere Flexo-Schaumbänder sind in 5...

GERGONNE, IHR KOMPLETTANBIETER FÜR ALLE IHRE SILIKON-WÄRMELEITPADS

Als einer der wenigen vollständig vertikal integrierten europäischen Anbieter garantiert GERGONNE seinen Kunden ein hohes Maß an Qualität und Kostenkontrolle. Wir bieten ein umfassendes Sortiment an Silikon-Wärmeleitpads (GERGOTIM) in folgenden...

DAUERHAFTE BEFESTIGUNGSLÖSUNG – FOKUS AUF UNSER DOPPELSEITIGES PE-SCHAUMKLEBEBAND X10080

Fokus auf unser doppelseitiges PE-Schaumband X10080 Unser doppelseitiges Polyethylen-Schaumband wird hauptsächlich für Verbindungs- und Befestigungsanwendungen zwischen zwei starren Oberflächen verwendet. Dank unserer WRAtech-Technologie (Weather Resistant Adhesive) bietet unser doppelseitiges Schaumband...

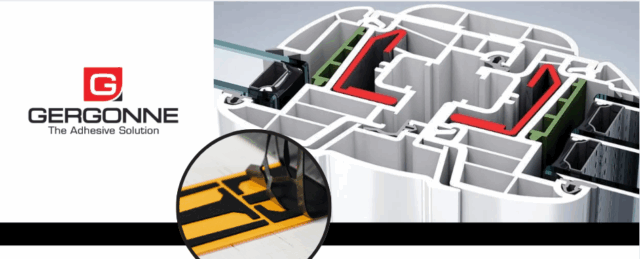

UNSERE DICHTUNGSLÖSUNGEN FÜR PROFILFUGEN

Unsere Dichtungen für Tischlerarbeiten, ein schlüsselfertiges Produkt Gergonne liefert Klebstoffmaterialien wie Polyethylenschaum oder EPDM-Zellkautschuk (in verschiedenen Farben und Dichten erhältlich), die in der Branche als perfekt geeignet für die Dichtungsanforderungen...

HOCHLEISTUNGSFÄHIGE PU-FOLIEN – UNSERE SOFT-TOUCH-PRODUKTE

Um den Anforderungen des Medizinmarktes gerecht zu werden, entwickelt Gergonne die Soft-Touch-Klebstoffe M312B15 und M317B15, hochleistungsfähige PU-Folien mit zahlreichen Vorteilen: 1: Überlegene Gleitfähigkeit für weniger Reibung 2: Leicht zu entfernender...

WELCHE KLEBSTOFFLÖSUNGEN FÜR BODENBELÄGE?

Unsere doppelseitigen Klebstoffe Die Vorteile unserer Klebstoffe für Bodenbeläge: Unsere Lösungen für alle Ihre Anforderungen Treppenstufen – für Treppenstufen aus PVC oder Metall, vermeidet das Bohren in den Untergrund. Unsere...

ORGANISIEREN UND SICHERN SIE IHRE INDUSTRIEFLÄCHEN MIT UNSEREN BODENMARKIERUNGSKLEBSTOFFEN

Was gibt es Besseres als den Jahresbeginn, um gute Vorsätze zu fassen und seine Räumlichkeiten neu zu organisieren? Wir haben die Lösung für Sie: unser Sortiment GERGOSIGN mit Klebebändern für...

UNSERE KLEBSTOFFLÖSUNGEN FÜR DIE LUFT- UND REGENDICHTIGKEIT VON GEBÄUDEN

Gergonne geht auf die Bedürfnisse seiner Kunden ein und verfügt über anerkanntes Know-how in der Forschung und Entwicklung sowie in der Herstellung von Klebstofflösungen für die Luft- und Regendichtigkeit. Damit...